High-Performance EMI/RFI Board-Level Shielding

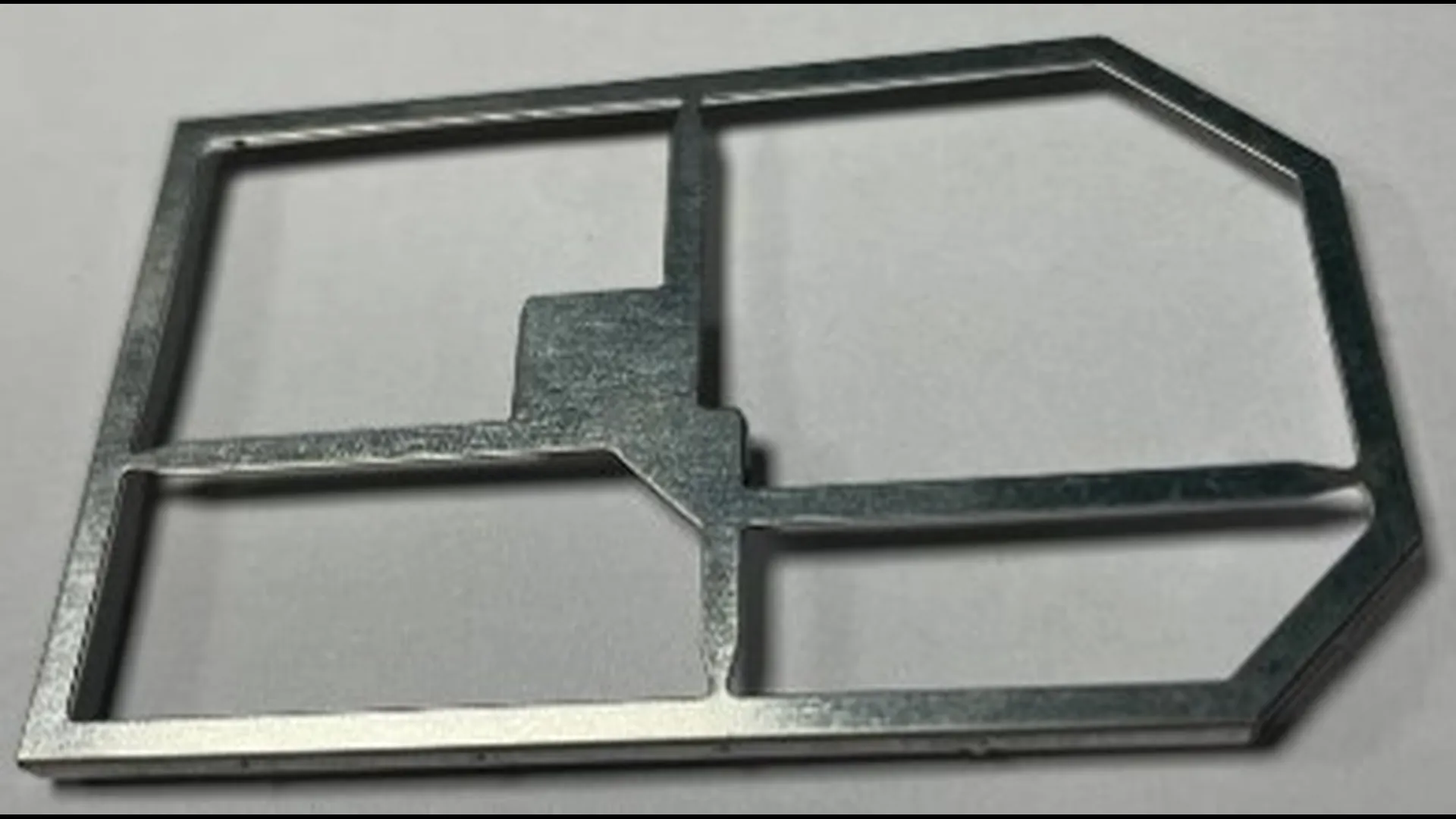

In modern electronics, dense circuit boards create a noisy environment where electromagnetic and radio frequency interference (EMI/RFI) can degrade or disrupt performance. FDCL engineers and manufactures high-performance, precision-stamped shielding solutions that isolate critical components, ensuring absolute signal integrity for the world's most demanding applications. We provide both standard catalog solutions and fully custom designs.

Standard Parts Catalogue

Select from our inventory of standard one-piece and two-piece shields. All models are available for quotation and can serve as a baseline for further customization.

Coming Soon

Our standard parts catalog is currently being finalized. In the meantime, our engineering team is ready to discuss your custom shielding requirements.

Capabilities & Materials

Our state-of-the-art facility is equipped to handle a comprehensive range of manufacturing processes, materials, and finishes. This allows us to produce EMI/RFI shields that meet your most precise requirements for performance, quality, and cost.

Bi-Metal

Coated

Coined

Compliant Pin (eye of the needle)

Countersunk Holes

Critical Dimensions

EB Welded

Embossed

Enameled

Eyelets

Flat

Formed

Heat-Treated

IDC Slots

Injection Molded

Inlay

Insert Molded

Multiple Stamping

Numbering

Powder Coated

Precious Metal Plated

Reeled

Riveted

Shape Critical

Skived

Stacked

Strain Relief

Surface Critical

Surface Mounted

Tapped

Threaded

Tip Coin

Tox Lock

Tuning Forks

Welded

Bi-Metal

Coated

Coined

Compliant Pin (eye of the needle)

Countersunk Holes

Critical Dimensions

EB Welded

Embossed

Enameled

Eyelets

Flat

Formed

Heat-Treated

IDC Slots

Injection Molded

Inlay

Insert Molded

Multiple Stamping

Numbering

Powder Coated

Precious Metal Plated

Reeled

Riveted

Shape Critical

Skived

Stacked

Strain Relief

Surface Critical

Surface Mounted

Tapped

Threaded

Tip Coin

Tox Lock

Tuning Forks

Welded

A Foundation of Quality, A Partnership in Innovation

Our Unwavering Commitment to Quality

At FDCL, quality is not a final check; it is a core principle embedded in our process. We ensure every part meets your exact specifications through a multi-layered quality system.

Quality Systems

100% Micron-Level Automated Optical Inspection (AOI)

ERP-integrated production systems

5S Manufacturing Principles

Statistical Process Control (SPC)

Certifications

Proven Performance Across Industries

Our EMI/RFI shielding solutions are trusted by leaders in the following sectors to protect their most critical assets:

Telecommunications (Routers, Switches, 5G Infrastructure)

Automotive (Infotainment, ADAS, ECU)

Medical Devices

Consumer Electronics

Industrial & IIoT